The Main Principles Of Uv Filtration

Table of ContentsHow Uv Filtration can Save You Time, Stress, and Money.Some Known Facts About Uv Filtration.The Buzz on Uv FiltrationSome Ideas on Uv Filtration You Should Know

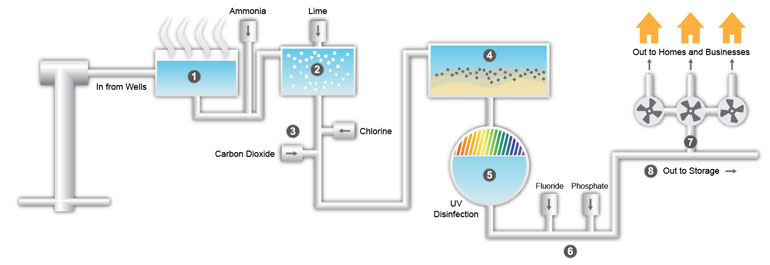

Elimination of taste and odor substances from the water.: Softens the water.: Filtering to eliminate small particles and disinfection to kill viruses as well as bacteria, and make certain an unsuitable atmosphere for infection and germs growth throughout the circulation system.

8 Stages of the Wastewater Process Phase One Bar Screening Elimination of big products from the influent to protect against damages to the facility's pumps, shutoffs and various other tools. The process of dealing with as well as recovering water from wastewater (any kind of water that has actually been used in residences, such as flushing toilets, washing dishes, or bathing, as well as some water from commercial use as well as tornado sewage systems) starts with the assumption that after it is treated it will be clean enough to reenter the setting.

The 8-Second Trick For Uv Filtration

According to the EPA, The Clean Water Act (CWA) establishes the fundamental framework for managing discharges of toxins into the waters of the USA as well as regulating quality criteria for surface area waters. Under the CWA, EPA sets wastewater criteria for market. The EPA has actually additionally created national water quality requirements suggestions for contaminants in surface area waters.

Related White Documents Select Products Phase 2 Testing Removal of grit by flowing the influent over/through a grit chamber. Fine grit that finds its method right into the influent demands to be gotten rid of to avoid the damage of pumps and also tools downstream (or effect water circulation). As well tiny to be evaluated out, this grit requires to be eliminated from the grit chamber.

Phase 4 Aeration Air is pumped right into the oygenation tank/basin to urge conversion of NH3 to NO3 and provide oxygen for germs to proceed to proliferate as well as grow. Once converted to NO3, the microorganisms remove/strip oxygen molecules from the nitrate particles and the nitrogen (N) is emitted as N2 (nitrogen gas) - uv filtration.

This begins in the oygenation storage tank. The primary feature of the aeration container is to pump oxygen into the tank to urge the malfunction of any natural material (and also the growth of the germs), along with guarantee there is adequate time for the natural material to be broken down.

10 Simple Techniques For Uv Filtration

This process is taken look at this web-site care of to offer the most effective problems for microbial growth. Oxygen gas [O2] degrees listed below 2 ppm will certainly exterminate the microorganisms, lowering effectiveness of the plant. Dissolved oxygen monitoring at this phase of the plant is important. Ammonia and also nitrate dimensions prevail to gauge exactly how efficient the bacteria are in transforming NH3 to N2.

Stage 5 Additional Clarifier Dealt with wastewater is pumped right into a secondary clarifier to enable any remaining natural debris to resolve out of treated water flow. As the influent departures the oygenation process, it streams into a second clarifier where, like the primary clarifier, any kind of really little solids (or fines) sink to the bottom of the storage tank.

With the improved focus of germs as part of the oygenation phase, there is a requirement to test recommended you read the outgoing effluent for microorganisms visibility or absence and to disinfect the water. This guarantees that more than specified focus of germs are not released right into the atmosphere. Chlorination is the most usual and also cost-effective sort of disinfection yet ozone and also UV sanitation are additionally raising in appeal.

The Facts About Uv Filtration Uncovered

Water is directed from the Head Tank to the Claricone clarifier. Water goes into the clarifier at the mixing area situated in the bottom of the Claricone - uv filtration. Lime is included in the water in this zone where it responds with the try this site calcium and the magnesium in the water to develop speeds up.

After adequate time, fragments comply with each various other as well as become bigger bits, or, floc, which is prone to settle in water. This process of floc formation is called flocculation. To assist in the flocculation of particles, an anionic polymer is added in the blending area of the cone. Clarification of water is accomplished by the seperation of put on hold solids from water by gravity.

The clarified water steps up slowly, ultimately passing over the effluent weir to the cone outlet as well as on the to filters for further therapy. The water plant incorporates a single phase lime softening operation to get rid of firmness. Hardness is caused by the presence of liquified bivalent as well as polyvalent metal ions, primarily calcium and also magnesium.

This is added both in the clearwell and the high solution discharge as water enters the circulation system. Hydrofluosilicic acid provides the source of fluoride, which is valuable in the avoidance of tooth decay in youngsters. A fluoride concentration of 1. 1-1. 2 mg/l is normally desirable in the plant faucet.